Experience Unparalleled Precision and Efficiency with Dry Ice Blasting

Experience the pinnacle of cleaning with dry ice Blasting, we seamlessly tailor solutions to meet the diverse needs of our customers in various industries. Bringing forward ICEsonic's cutting-edge technology, we harness subzero temperatures to bring precision and efficiency.

Whether you are looking to purchase a machine from our ICEsonic range or require a blast solution, our expert offerings span a wide spectrum of industries and applications.

OFFICIAL ICEsonic DISTRIBUTORS

EXPLORE THE RANGE

As the UK's official ICEsonic distributor, we provide access to a wide selection of dry ice blasting machines, each tailored to specific cleaning requirements. Whether you need a compact model for smaller tasks or a robust machine for heavy-duty applications, we have the right solution for you.

Transform your cleaning process with the power of ICEsonic dry ice blasting. Contact Industrial Field Services today to learn more about our products and how they can benefit your business.

Benefits of Dry Ice Blasting

- Non-Abrasive Cleaning: Safely cleans surfaces without scratching or damaging them.

- Environmentally Friendly: Uses CO2, a naturally occurring substance, and produces no secondary waste.

- Versatile Applications: Effective for a wide range of surfaces, including metal, wood, plastic, and more.

- Minimized Downtime: Can be performed without disassembling equipment, reducing maintenance time.

- No Water Damage: Ideal for electrical and sensitive equipment as it does not involve water or chemicals.

Applications of Dry Ice Blasting

- Industrial Cleaning: Removes grease, oil, and grime from machinery, tools, and production equipment.

- Surface Preparation: Strips paint, rust, and other coatings from surfaces, preparing them for repainting or refurbishment.

- Food Industry: Cleans processing equipment, conveyor belts, and molds without using chemicals, ensuring compliance with hygiene standards.

- Automotive: Cleans engines, molds, and assemblies, enhancing performance and longevity.

- Historical Restoration: Safely removes soot, mold, and other contaminants from historical buildings and artifacts without damaging delicate surfaces.

The materials & surfaces which can be cleaned using innovative dry ice blasting are almost limitless.

The process is non-abrasive, non-toxic and non-conductive; it does not use chemicals, nor does it generate secondary waste.

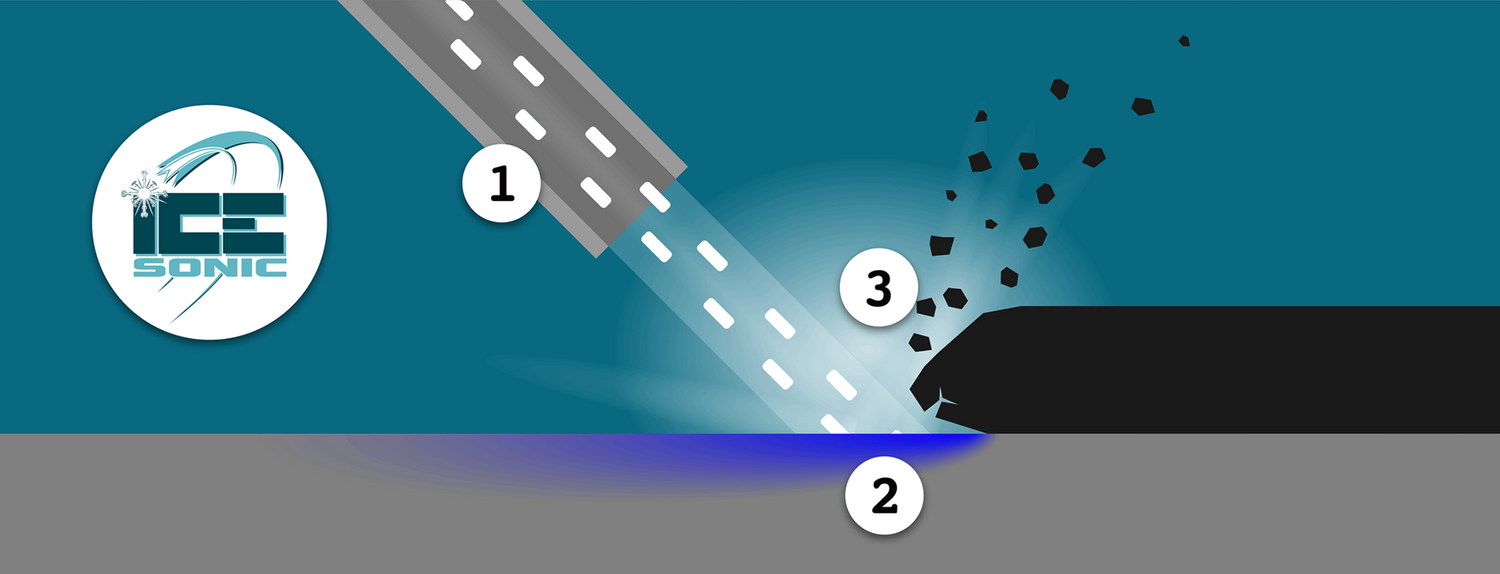

HOW IT WORKS

Dry ice blasting involves accelerating dry ice pellets at high speeds using compressed air. When the pellets hit the surface, they sublimate (turn directly from solid to gas) on impact, creating mini-explosions that lift away dirt, grime, paint, and other unwanted materials. This process is non-abrasive, non-conductive, and free from secondary waste, as the dry ice evaporates completely, leaving no residue behind.

-

Automotive Restoration

-

Oak & Beam Restoration

-

Manufacturing

-

Fire Damage

INDUSTRIES

Our services adapt to the unique requirements of each industry, providing versatile solutions for both mobile and shop applications. Discover how we redefine cleanliness standards and operational excellence across diverse sectors. Choose Industrial Field Services Ltd for cutting-edge ice blasting services tailored to your industry's specific needs.

- Automotive

- Manufacturing and Foundries

- Electronics and Technology

- Aerospace and Aviation

- Food and Beverage Processing

- Healthcare and Pharmaceuticals

- Historical Restoration

- Oil and Gas Industry