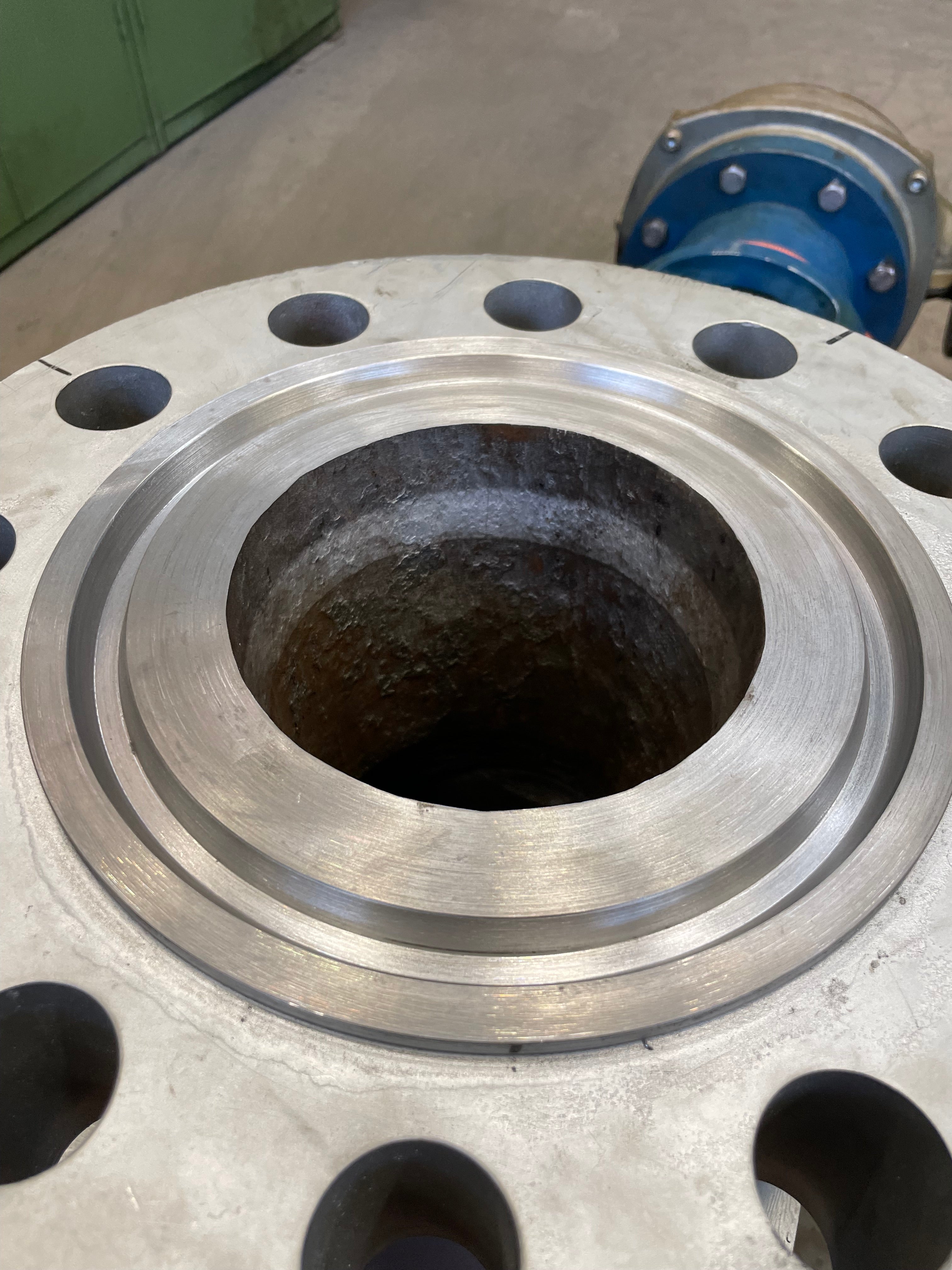

FLANGE FACING & JOINT RECTIFICATION

Flange facing is the process of machining the mating surface of a flange to restore its flatness and create a smooth, even finish. This ensures a proper seal when the flange is bolted together, preventing leaks in piping systems and machinery.

Key Aspects of Flange Facing

- Surface Restoration: Restores flatness and smoothness to flange surfaces.

- Seal Integrity: Ensures a proper seal to prevent leaks.

- Versatility: Suitable for various flange sizes and materials.

- Onsite Capabilities: Portable machines allow for onsite flange facing.

- Improved Performance: Enhances the reliability and safety of piping systems.

Common Applications

- Oil and Gas: Restores flanges in pipelines and refineries.

- Construction: Ensures proper sealing in building infrastructure.

- Manufacturing: Maintains flanges in machinery and equipment.

- Shipbuilding: Prepares flanges for marine vessel construction and repair.

Process Overview

- Setup: Align the flange facing machine with the flange surface.

- Facing: Machine the flange surface to restore flatness and smoothness.

- Measurement: Ensure the flange meets required flatness and finish specifications.

- Finishing: Achieve a clean, even surface for optimal sealing.

Benefits

- Cost-Effective: Extends the life of existing flanges, reducing replacement costs.

- Time-Saving: Onsite capabilities minimize downtime and transport costs.

- Precision: Ensures flat, smooth surfaces for better sealing.

- Safety: Prevents leaks and enhances the reliability of piping systems.

Applications:

-

RTJ Profiles

-

Raised Face Flanges

-

Gramophone Reinstatement

-

Greylock Hubs & Flanges

-

Corrosion & Damaged Faces

-

Angled Faces & Bores

-

Sealing Faces & Joints

-

Weld Overlaid Bores & Faces